Understanding the Manufactured Home Setup Process

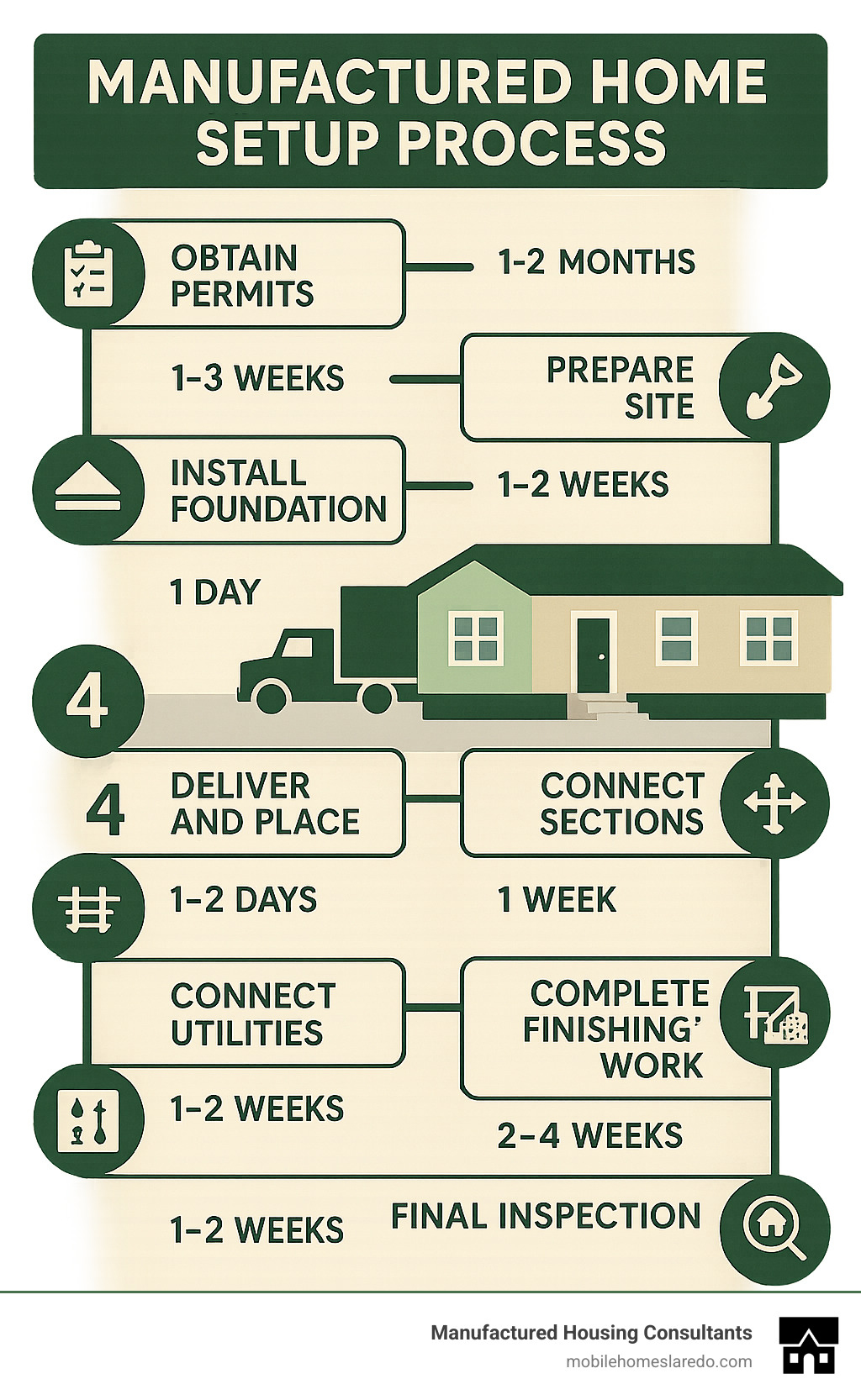

Manufactured home set up is the complete process of preparing land, delivering, placing, and finishing a factory-built home on your property. If you’re looking for a quick overview of what’s involved, here are the essential steps:

- Obtain permits from local authorities

- Prepare the site with proper grading and drainage

- Install a foundation (concrete, gravel pad, or basement)

- Deliver and place the home on the foundation

- Connect all sections for multi-section homes

- Anchor and secure the home to the foundation

- Connect utilities (water, sewer, electric, gas)

- Complete finishing work (skirting, steps, decks)

- Final inspection and occupancy approval

The entire process typically takes about 6 months from purchase to move-in, with the actual home placement taking just one day.

Manufactured homes (formerly called mobile homes) offer an affordable path to homeownership with modern amenities and customizable designs. Built in climate-controlled factories to federal HUD standards, these homes arrive in sections and are assembled on your prepared site.

Unlike traditional site-built homes, manufactured homes can be set up for a fraction of the cost while still providing quality construction. The setup process is critical to your home’s long-term stability, appearance, and value. As one installer notes, “A properly prepared and leveled lot allows for a lower profile appearance, fewer steps at entry, and a sturdier foundation.”

Whether you’re placing your home in a manufactured home community or on private land, understanding the setup process helps ensure your investment remains secure for decades. The right foundation, proper anchoring, and correct utility connections are not just code requirements—they’re essential for your home’s warranty and your family’s safety.

Step-by-Step Manufactured Home Set Up Process

The journey from choosing your manufactured home to moving in involves several critical phases. Each step builds upon the previous one, creating a solid foundation for your new home—both literally and figuratively. At Manufactured Housing Consultants, we guide our customers through this journey with expertise gained from years of experience in the Texas manufactured housing market.

Land Prep & Permits for Manufactured Home Set Up

Before your new home arrives, proper site preparation is essential. This first phase sets the stage for everything that follows and can significantly impact your home’s longevity.

Site Selection and Evaluation

Finding the perfect spot for your home matters more than you might think. The ideal site should be slightly liftd for good drainage, easily accessible for delivery trucks (watch out for those low-hanging branches!), and free from organic materials like peat that can cause settling issues.

“I always tell my clients to think about both today and tomorrow,” says one of our site specialists. “That beautiful spot under the trees might seem perfect until you realize the delivery truck can’t steer between them.”

At Manufactured Housing Consultants, we offer free site inspections throughout Texas to help you identify potential issues before they become expensive headaches.

Soil Testing and Preparation

Your soil literally supports your entire investment, so we take it seriously. Using a pocket penetrometer, we measure how much weight your soil can support. We’ll also check drainage patterns to ensure water flows away from your future home.

Proper compaction is critical—the ground must be compacted to at least 90% density in 4-inch lifts. We create what pros call a “crown” in the soil—a slight elevation in the center that channels water away from your home.

As one customer told us after a heavy rain, “I’m so glad you insisted on that extra grading work. My neighbor’s yard was underwater, but mine stayed dry as a bone!”

Permits and Regulatory Requirements

Navigating the permit maze can be overwhelming, but we’ve got you covered. Depending on your location, you’ll need zoning approval, building permits, moving permits, and possibly septic and electrical permits.

Manufactured home set up must comply with HUD installation standards, which establish minimum requirements for every aspect of installation. Many areas also require licensed installers—for example, Tennessee requires installers to complete a 15-hour course and pass an exam, with $1,000 penalties for unlicensed work.

We handle all the paperwork, so you don’t have to become an overnight expert in local building codes.

Clearing and Grading

Once permits are in hand, the real change begins. We’ll clear vegetation and debris, grade the land (typically with a 1/2 inch per foot slope away from the home), and install erosion control if needed. We’ll also mark utility line locations and plan trenches for your connections.

This phase can take anywhere from a few weeks to several months, depending on your terrain and the weather. As one of our project managers likes to say, “We can’t control Mother Nature, but we can work with her schedule.”

Choosing the Right Foundation & Home Placement

Your foundation choice affects everything from your home’s appearance to its long-term stability and even its classification as “real property” for financing and tax purposes.

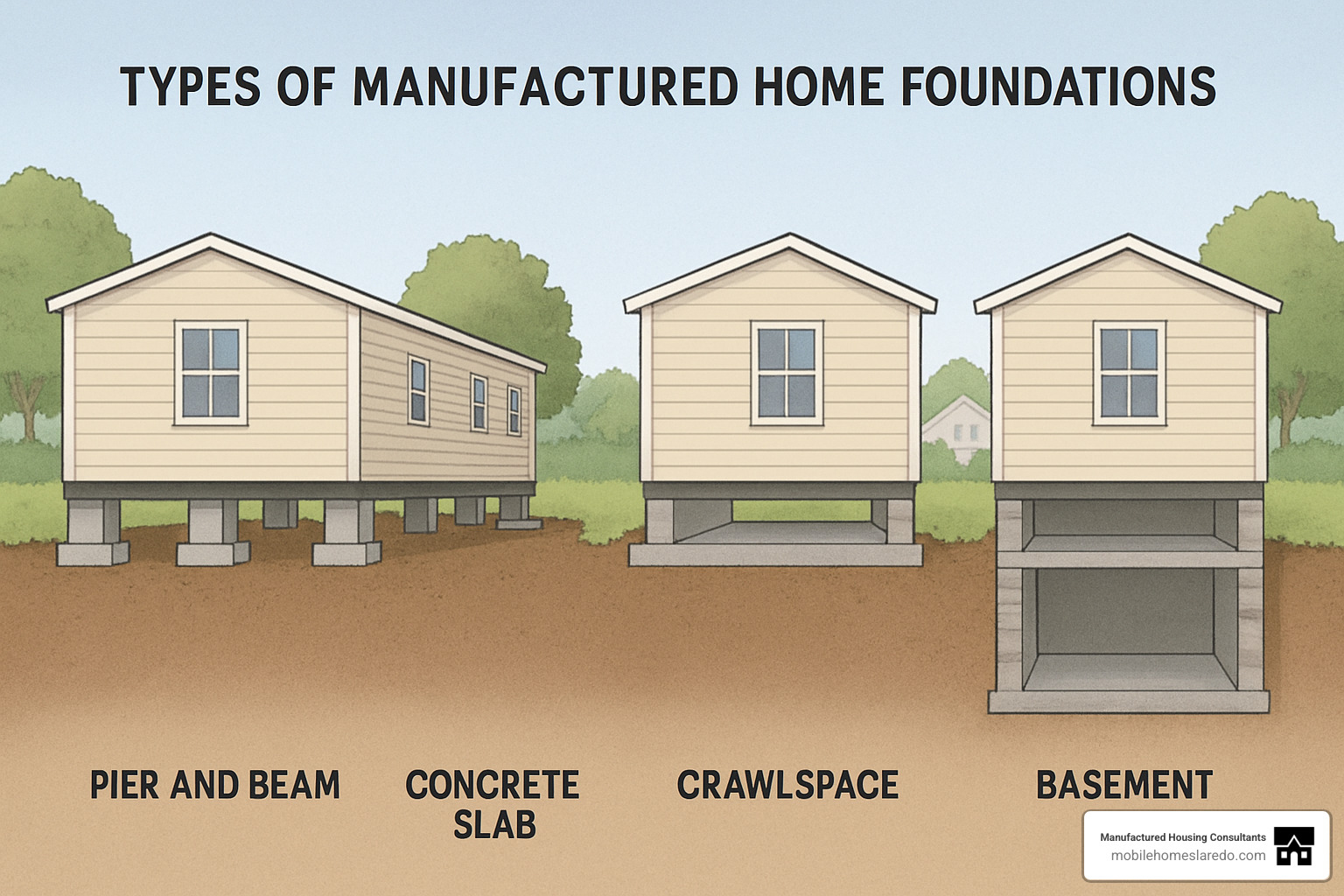

Foundation Options

Pier and Beam Foundation offers affordability and quick installation. Richard Imus, an industry expert, recommends “a 4-inch compacted crushed gravel pad with an earthquake/wind tie-down system” as a reliable base that’s accepted in most areas.

Concrete Slab Foundation provides maximum stability and is often required in flood-prone or high-wind areas. For these foundations, we ensure the appropriate mix strength (typically 3,000 psi minimum) and embed utility sleeves before pouring.

Crawlspace Foundation creates accessible space beneath your home for utilities and offers excellent protection from moisture—especially important in humid parts of Texas.

Basement Foundation gives you additional living space and maximum stability. This option effectively transforms your manufactured home into a structure indistinguishable from site-built housing.

| Foundation Type | Cost Range | Permanence | Benefits | Best For |

|---|---|---|---|---|

| Pier & Beam | $2,000-$5,000 | Low-Medium | Affordable, quick installation | Temporary locations, flat sites |

| Concrete Slab | $7,000-$15,000 | High | Stable, low profile, weather resistant | Permanent installation, flood zones |

| Crawlspace | $6,000-$12,000 | Medium-High | Access to utilities, good in varied terrain | Sloped sites, areas with high water table |

| Basement | $15,000-$30,000 | Very High | Additional living space, maximum stability | Permanent homes, cold climates |

Frost Line and Climate Considerations

While the deep frost lines of northern states aren’t usually a concern in Texas, we have our own climate challenges. Along the coast, we need stronger wind resistance systems. In flood-prone areas, we’ll recommend liftd foundations. And in our scorching summers, proper air circulation beneath your home becomes essential for comfort and efficiency.

“Texas weather throws a little bit of everything at us,” one of our foundation specialists notes. “We design for the worst days, not just the average ones.”

Vapor Barrier Requirements

One often-overlooked element is the vapor retarder—typically 6-mil polyethylene sheeting—installed under any home that will have skirting. This critical barrier prevents ground moisture from causing problems with your flooring, insulation, and structural components.

I’ve seen homes without proper vapor barriers where the floor joists started rotting within just a few years. A small investment here saves thousands in repairs later.

Learn more about Types of Foundations for Mobile Homes on our website.

Home Delivery and Placement

Delivery day is exciting! Specialized “toter” trucks will transport your home sections to your prepared site. We’ll help ensure the route is clear of obstacles, coordinate with local authorities for any road closures or escorts, and have your foundation completely ready before delivery day.

Placement requires precision and specialized equipment. For multi-section homes, alignment must be exact. Our professional installers use water levels to ensure perfect leveling while safety cribbing supports the home during the process.

“Installing the home as low to the ground as legally permissible improves both appearance and structural stability,” our installation team leader explains. This approach minimizes the need for steps and reduces the height of skirting required, giving your home a more custom, site-built look.

Anchoring, Utilities, and Finishing Touches in Manufactured Home Set Up

Once your home is placed on its foundation, several critical steps remain before you can start arranging furniture and hanging pictures.

Anchoring Systems

Proper anchoring isn’t just about meeting codes—it’s about keeping your family safe during severe weather. Your anchoring system includes ground anchors (either auger-type driven into soil or concrete anchors for slab foundations) and tie-downs (frame ties connecting the chassis to ground anchors and vertical ties securing the top in high-wind areas).

In areas prone to seismic activity, Earthquake Resistant Bracing Systems (ERBS) distribute forces during an earthquake and prevent the home from sliding off its foundation.

“Properly tied-down homes can withstand winds over 110 mph,” according to manufactured housing experts. We’ve seen this during Texas storms—the homes with proper anchoring systems remained secure while others suffered damage.

Utility Connections

Connecting your home to essential services requires coordination with various professionals. For water connections, we ensure proper pressure testing of all lines and appropriate insulation in colder areas. Sewer/septic connections need the correct slope for proper drainage and venting according to plumbing codes.

Electrical connections include proper grounding, circuit testing, and panel labeling, while gas connections require pressure testing for leaks, proper venting for appliances, and safety shutoff valve installation.

All utility connections require permits and inspections before use. We coordinate these installations through licensed professionals familiar with manufactured home set up requirements, saving you from having to juggle multiple contractors.

Marriage Line Connections

For multi-section homes, the connections between sections (marriage lines) must be properly sealed. We install gaskets between sections, pull them together with specialized equipment, and permanently join the roof, walls, and floors. All seams are sealed against weather infiltration, and interior finishes like drywall and trim are completed at connection points.

“The marriage line is where craftsmanship really shows,” our lead installer often says. “When we’re done, you shouldn’t be able to tell where one section ends and another begins.”

Skirting and Exterior Finishing

Skirting (also called underpinning) does more than just make your home look finished—it regulates temperature beneath your home, prevents animal intrusion, and protects plumbing in cold weather.

You can choose from vinyl, metal, brick, or concrete skirting, each offering different benefits. Many of our customers are surprised by how dramatically the right skirting can transform the appearance of their home. Learn more about Skirting for Manufactured Home options on our website.

We’ll also help with additional exterior finishing touches like entry steps, porches, decks, gutters, downspouts, and basic landscaping for erosion control.

All aspects of manufactured home set up must comply with the Model Manufactured Home Installation Standards, which provide detailed requirements for every installation element.

Timeline, Costs, and Common Mistakes

Understanding when you’ll be able to move in and how much it will cost helps prevent unwelcome surprises during your manufactured home set up journey.

Typical Timeline

From purchase to that magical moment when you turn the key in your new front door typically takes about 6 months. The process breaks down like this:

Site preparation takes a few weeks to several months, including 2-4 weeks for permitting, 1-3 weeks for land clearing and grading, and 1-4 weeks for foundation construction.

Home delivery and placement happens in just one day—it’s amazing to watch your home arrive and take its place on your property!

Finishing work requires 3-4 weeks, including utility connections (1 week), interior finishing (1-2 weeks), and exterior work like skirting and steps (1-2 weeks).

Final inspections and approval typically take 1-2 weeks before you can officially move in.

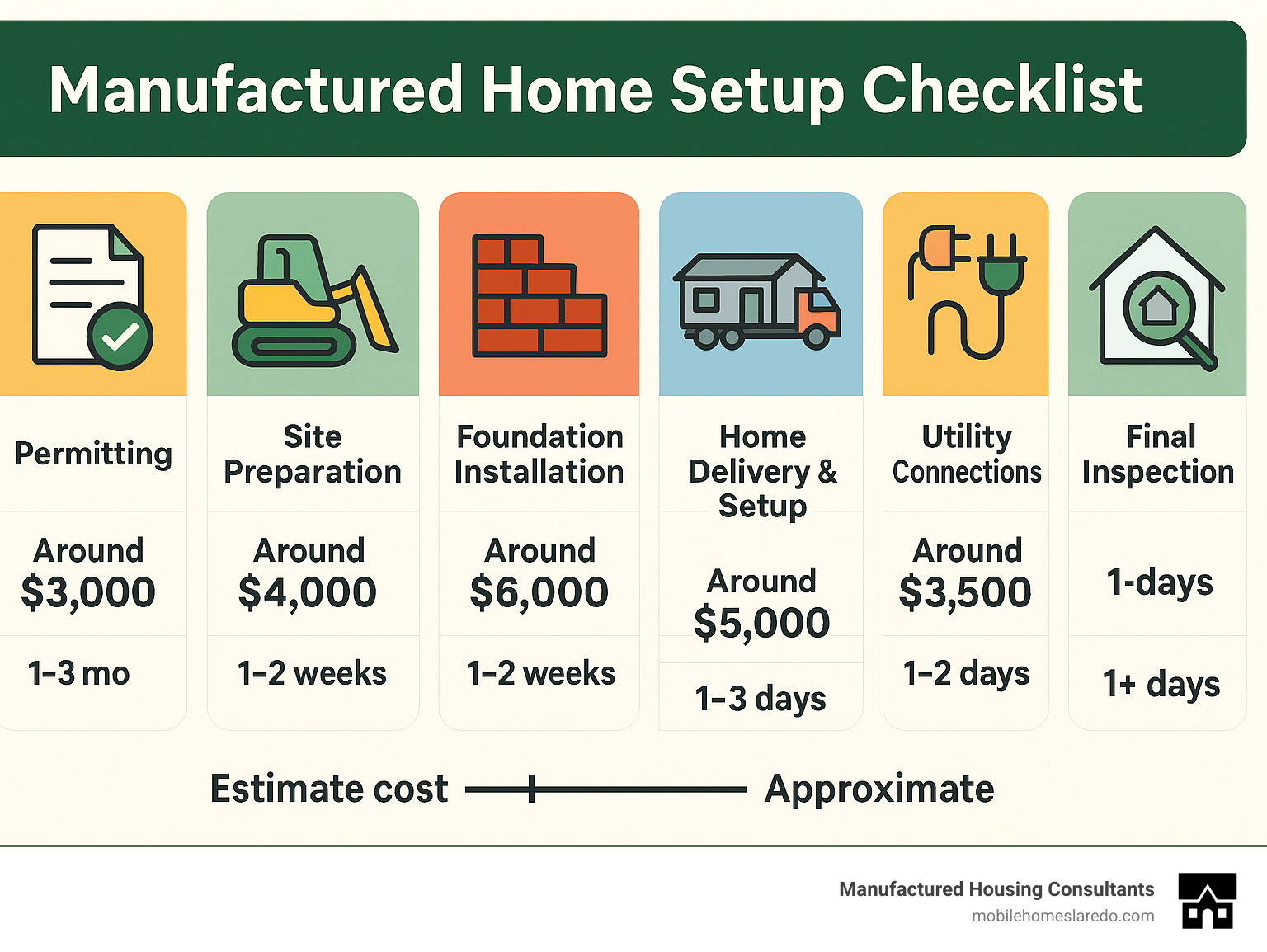

Cost Factors

The cost of manufactured home set up varies based on several factors. Site preparation costs include land clearing ($500-$5,000 depending on vegetation and terrain), grading and drainage ($1,000-$3,000), and possibly access road improvements ($2,000-$10,000 if needed).

Foundation costs range from $2,000-$5,000 for pier and beam, $7,000-$15,000 for concrete slab, and $15,000-$30,000 for a basement.

Delivery costs include transport fees ($2-$5 per mile per section), escort vehicles if required ($1.50-$2.50 per mile), and crane services if needed ($1,000-$3,000).

Utility connection costs cover water hookup ($500-$2,000), sewer/septic ($3,000-$10,000), electrical ($1,000-$3,000), and gas ($800-$2,000).

Finishing costs include skirting ($1,500-$4,000), steps and porches ($1,000-$5,000), and driveway installation ($2,000-$6,000).

At Manufactured Housing Consultants, we provide detailed cost estimates upfront, so you know exactly what to expect. Learn more about Mobile Home Delivery and Set Up Costs on our website.

Professional vs. DIY Installation

While it might be tempting to save money with DIY installation, the actual home setup should be performed by licensed professionals. Many states require installer licensing—Tennessee, for example, imposes a $1,000 penalty per home for unlicensed installation.

Improper installation can void your home’s warranty, and professional installation includes liability insurance coverage. Plus, specialized equipment and expertise are required for safe installation.

As one customer told us after watching the installation process, “I thought I could handle it myself until I saw what was involved. No way would I have gotten that right!”

Common Mistakes to Avoid

We’ve seen plenty of installation issues over the years. Inadequate site preparation like failing to properly grade for drainage or insufficient soil compaction can cause serious problems down the road.

Foundation problems such as improper pier spacing or incorrect footing size for soil conditions lead to settling and structural issues. Anchoring issues like using the wrong type of anchors for your soil or improper tensioning of straps compromise your home’s safety.

Utility connection errors including inadequate slope for sewer lines or improper electrical grounding can be costly to fix later. And don’t forget ongoing maintenance like checking level annually and maintaining proper drainage around the foundation.

“Finding a professional mobile home setup contractor whenever possible is advised,” recommends industry expert Richard Imus. At Manufactured Housing Consultants, we work only with licensed, experienced installers who understand the unique requirements of Texas soils and climate conditions.

Conclusion & Next Steps

Turning a factory-built house into your dream home isn’t just about delivery day – it’s about creating a solid foundation (literally and figuratively) that will support your life for decades to come. A properly executed manufactured home set up makes all the difference between a house that ages gracefully and one that develops problems down the road.

We’ve walked through every step of the journey together – from that first exciting site evaluation to the final building inspector’s approval. Now, let’s talk about how to make this process as smooth as possible for your family.

At Manufactured Housing Consultants, we’ve helped hundreds of Texas families steer this path, and we’ve learned a thing or two along the way. Our customers often tell us the same thing: “I wish I’d known how much easier this could be with the right help!”

That’s exactly why we’ve built our business around simplifying the manufactured home experience. Our comprehensive approach includes:

Free site evaluations that catch potential problems before they cost you money. As Maria from San Antonio told us, “Their inspector spotted drainage issues I never would have noticed until it was too late.”

Guaranteed lowest prices on quality homes from 11 top manufacturers – because affordable homeownership shouldn’t mean compromising on quality.

Specialized financing options designed specifically for manufactured homes, with solutions for all credit situations. Many lenders don’t understand the unique aspects of manufactured housing, but our financing partners do.

FICO Score Improvement Program that helps many customers qualify for better rates, sometimes saving thousands over the life of their loan.

Complete setup coordination that handles everything from permitting headaches to final inspection details. We coordinate all the moving parts so you don’t have to become an expert in manufactured home installation overnight.

Our Laredo location serves as home base, but our team works with customers throughout Texas. We understand the unique challenges of different regions – from the coastal considerations near Corpus Christi to the expansive soils around Dallas-Fort Worth.

Checklist infographic we shared earlier? That’s your roadmap to success. Keep it handy as you move forward, and don’t hesitate to reach out with questions about any step in the process.

The beauty of manufactured homes is that they offer the same comfort, value, and longevity as traditional construction, often at half the price. But that value proposition depends entirely on proper installation. By understanding the process and working with experienced professionals, you’re setting yourself up for success.

Whether you’re dreaming of a cozy single-wide nestled in the Hill Country or a spacious double-wide with all the modern touches, we’re here to help make that dream a reality. Our team has guided countless families through this journey, and we’d be honored to help yours too.

Ready to take the next step? Contact us to schedule your free site evaluation or browse our extensive selection of quality homes. Your path to affordable homeownership starts with a conversation about your needs, your land, and your vision for the future.

After all, we’re not just setting up houses – we’re helping build homes where Texas families will create memories for generations to come.