What You Need to Know About Mobile Home Installation

Mobile home installation is the process of properly setting up a manufactured home on a prepared site, which includes foundation construction, home assembly, utility connections, and skirting application. In most states, including Washington, this work must be performed by a certified installer to ensure safety, compliance with regulations, and warranty validity.

“Improper manufactured home installation is responsible for more than half of all complaints from manufactured home owners in Washington State.”

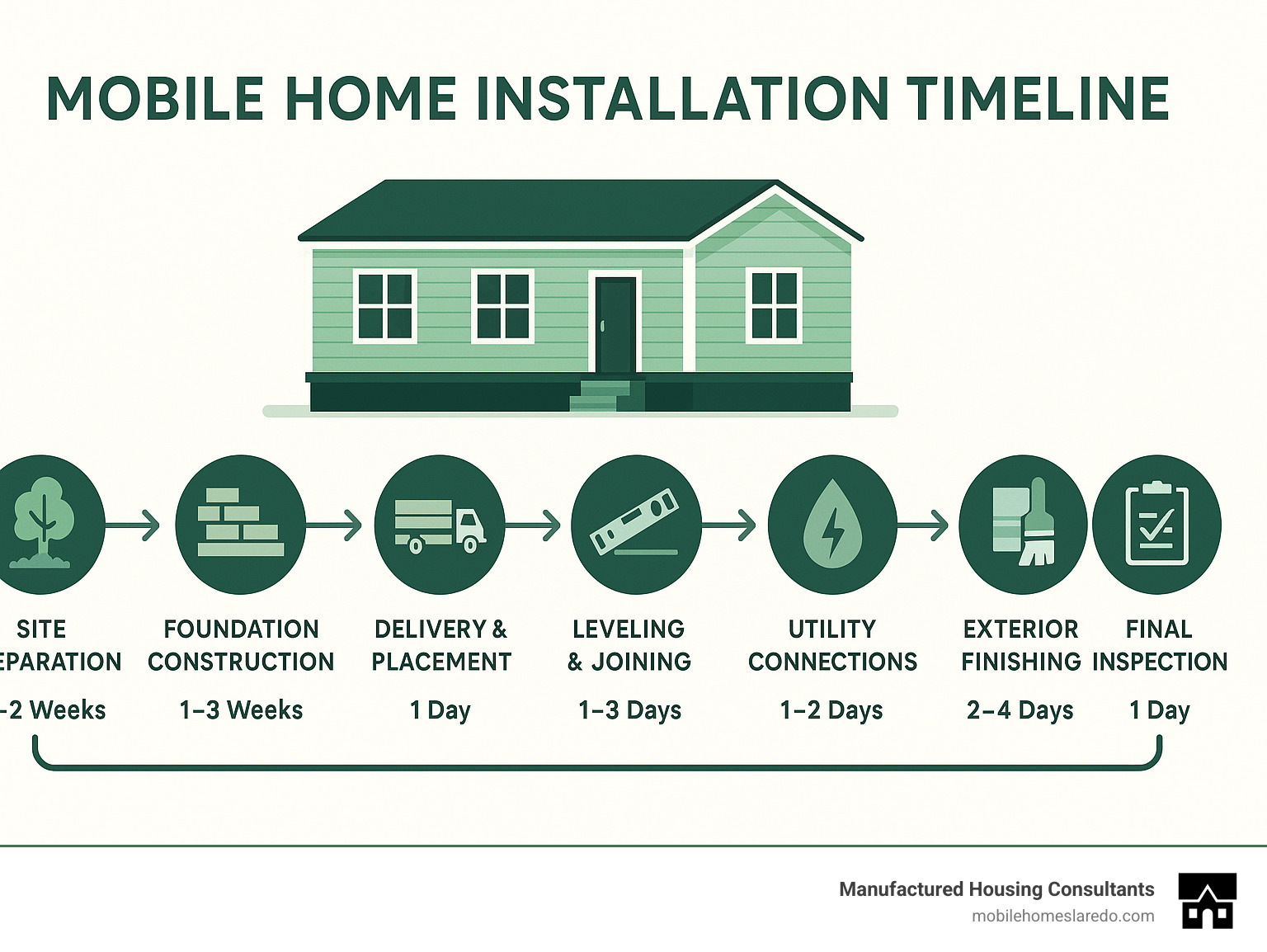

Quick Guide to Mobile Home Installation:

- Site Preparation – Clear land, grade for drainage, perform soil tests

- Foundation Construction – Build appropriate foundation based on soil and local codes

- Delivery & Placement – Transport home sections to site and position on foundation

- Leveling & Joining – Level the home and connect multiple sections if applicable

- Utility Connections – Hook up water, sewer, electrical, and gas services

- Exterior Finishing – Install skirting, steps, and weatherproofing

- Final Inspection – Obtain certificate of occupancy after passing all inspections

While a manufactured home can be built in a factory in less than a week, the complete installation process typically takes several weeks to complete due to site preparation, utility connections, and required inspections. Costs can range from $1,500 for simple setups to $20,000+ for complex installations depending on your location, site conditions, and home size.

If you’re considering purchasing a mobile home, understanding this installation process is crucial for proper budgeting, timeline planning, and ensuring your new home is safe and properly set up for years of trouble-free living.

Step-By-Step Mobile Home Installation Guide

When you purchase a manufactured home from us at Manufactured Housing Consultants, we want you to feel confident about what happens between signing your paperwork and walking through the front door of your new home. The mobile home installation process involves several key steps that build upon each other to ensure your home stands strong for years to come.

Step 1 — Site Prep & Foundation Selection

Think of site preparation as laying the groundwork for your future happiness—because it literally is! This first step can make or break your entire installation experience.

Good site prep starts with clearing the land completely—removing all vegetation, stumps, rocks, and debris from where your home will sit. Next comes soil testing to determine how much weight your soil can bear (typically we assume 1,500 pounds per square foot unless tests show otherwise).

Proper drainage is essential, so we’ll grade the land with at least a ½ inch slope per foot for the first 10 feet around your foundation. We’ll also verify there’s enough access—at least 14 feet of vertical clearance and 12 feet of road width—for the delivery trucks to reach your property.

Choosing the right foundation is one of your most important decisions. Your options include:

Floating Slab – A simple concrete pad that “floats” on the ground without deep footings. It’s cost-effective but best for stable soils.

Pier and Beam – The most common option using concrete or block piers to support your home’s frame. It’s affordable and works well in most situations.

Crawl Space – Similar to pier and beam but with perimeter walls that create an enclosed space beneath your home.

Basement – A full basement with concrete walls and floor. It’s the most expensive option but adds valuable living space.

Each foundation type comes with different costs:

| Foundation Type | Single-Wide Cost | Double-Wide Cost |

|---|---|---|

| Pier & Beam | $1,000-$2,000 | $2,000-$4,000 |

| Floating Slab | $4,000-$7,000 | $6,000-$15,000 |

| Crawl Space | $6,000-$12,000 | $8,000-$20,000 |

| Basement | $10,000-$15,000 | $12,000-$25,000 |

For homes in challenging environments like flood plains or earthquake zones, you might need a specially engineered foundation. Whatever type you choose, we’ll ensure it complies with the Model Manufactured Home Installation Standard (24 CFR Part 3285).

Don’t forget the vapor barrier! We always install a minimum 6-mil black polyethylene sheeting under your home with at least 12 inches of overlap at the seams. This simple step prevents ground moisture from causing costly problems down the road.

Want to learn more about foundation options? Check out our Manufactured Home Foundation Guide.

Step 2 — Delivery, Blocking & Leveling

The day your home arrives is exciting! But before the first section rolls onto your property, we’ve done careful planning to ensure a smooth delivery.

We start with a route survey to make sure the delivery trucks can safely steer to your site. Those big homes need plenty of room—at least 14 feet of vertical clearance for power lines and tree branches, and 12 feet of road width. For particularly challenging sites, we might use specialized equipment like a crawler to position your home precisely.

Once your home arrives, our team begins the careful process of blocking and leveling. We’ll place support piers according to the manufacturer’s specifications—typically 24 inches from the ends and no more than 120 inches apart. Using laser levels, we’ll ensure your home sits perfectly level (adjacent piers shouldn’t differ by more than ¼ inch).

For multi-section homes, aligning the marriage line (where sections join) requires special attention and skill. Once everything is secure, we’ll remove the transportation equipment like tires, axles, and hitches.

Proper leveling isn’t just about comfort—it’s critical for structural integrity and warranty purposes. Many manufacturers will void warranties if a home isn’t properly leveled during installation. That’s why at Manufactured Housing Consultants, we work only with experienced crews who understand the importance of getting this step right the first time.

Curious about delivery costs? Learn more about Mobile Home Delivery and Set Up Costs.

Step 3 — Mobile Home Installation Anchoring & Utility Hookups

With your home positioned and leveled, it’s time to anchor it securely and connect the utilities—steps that ensure both safety and comfort.

Since July 1996, all manufactured homes installed in Washington State must be properly anchored. This isn’t just red tape—it’s an essential safety measure that protects your home from wind damage and shifting.

The anchoring process begins by determining your location’s HUD-designated wind zone, which dictates specific requirements. We’ll install ground anchors that resist a working load of 3,150 pounds and an ultimate load of 4,725 pounds, connecting them to your home’s frame with approved straps. In earthquake-prone areas, we’ll add special bracing systems for extra protection.

Next comes connecting the utilities—the systems that make your house a functioning home:

Electrical connections involve hooking up to either a power pole or underground service. Safety is paramount here.

Plumbing connections include water line hookups, sewer or septic connections, and interior plumbing crossovers for multi-section homes.

Gas connections for natural gas or propane require careful installation and pressure testing to ensure there are no leaks.

HVAC connections complete your heating and cooling system, including any crossover ducts between sections.

For multi-section homes, properly connecting utilities between sections is an art as much as a science. Water lines, drain lines, electrical wiring, HVAC ducts, and gas lines must all be seamlessly joined according to manufacturer specifications.

Don’t forget about ground moisture control! We always install a 6-mil polyethylene vapor retarder under your entire home, with seams overlapped at least 12 inches. This simple step prevents moisture damage and helps maintain healthy indoor air quality.

Need to move an existing home? Learn about our Mobile Home Relocation Services.

Step 4 — Skirting, Decks & Exterior Finishes

The final phase of your mobile home installation adds those finishing touches that transform a manufactured house into your home sweet home.

Skirting isn’t just about looks—though it certainly creates a finished appearance by concealing the space beneath your home. It also keeps out curious critters and debris while helping insulate your home and protect pipes from freezing in winter.

We offer several skirting materials to match your style and budget, including vinyl (the most popular choice), metal, brick or stone, concrete block, and composite materials. Whatever you choose, we ensure proper installation with adequate ventilation (1 square foot of vent area per 150 square feet of under-floor area) and an access door (minimum 18″ × 24″) for maintenance.

Other exterior finishing elements include steps and landings that meet local building codes, optional decks and porches that expand your living space, and for multi-section homes, ridge cap sealing to ensure the roof connection is watertight. We’ll also install exterior trim around doors, windows, and corners for that polished look.

Here’s a helpful tip: While it might seem appealing to install your home high off the ground, keeping it lower (while maintaining required clearances) minimizes the amount of skirting needed and reduces the number of steps, making your home more accessible for everyone.

At Manufactured Housing Consultants, we take pride in creating beautiful, finished homes that you’ll be proud to show off to friends and family. Our installation teams pay attention to every detail, from proper ventilation to secure attachments, ensuring your skirting looks great and performs its important functions.

Want to explore skirting options? Check out our guide to Skirting for Manufactured Home.

Permits, Costs & Final Walk-Through

The paperwork and financial side of mobile home installation might not be as exciting as watching your new home come together, but they’re just as important for a smooth experience. Let’s walk through what you need to know about permits, inspections, and budgeting for your manufactured home setup.

Permits, Certification Tags & Code Compliance

Before the first piece of equipment touches your property, you’ll need the proper paperwork in hand. Think of permits as your official permission slip to proceed—and yes, they’re absolutely necessary!

Most locations require several different permits for your mobile home installation, including a main setup permit, plus separate ones for electrical, plumbing, and HVAC work. If you’re installing a septic system or well, those need their own permits too.

Washington State (like many others) requires a certified installer to handle your home setup. These professionals have completed specialized training and passed certification exams—and they’ll attach a certification tag to your home when the job is finished. This tag isn’t just a sticker; it’s proof your home was installed properly.

Good news for the DIY-minded: some aspects of setup don’t require a certified installer. You can handle site grading, exterior utility hookups beyond the building site, painting, flooring, and a few other tasks yourself. Licensed trade professionals can also perform work within their scope without being certified installers.

Your installation must comply with a multi-layered cake of regulations:

- The federal HUD Code (24 CFR 3285) forms the foundation layer

- State regulations add another layer (often with stricter requirements)

- Local building codes add the next layer for site-specific rules

- The manufacturer’s instructions are the frosting on top—and must be followed to keep your warranty valid

If you’re in a flood plain, seismic zone, or high wind area, you’ll face additional requirements. These special situations often call for engineer-designed foundations and beefed-up anchoring systems.

Feeling ambitious? In some states, including Washington, homeowners can install their own manufactured homes after completing a training course and purchasing a certification tag. While this might save money, it’s a big undertaking that requires significant knowledge—not recommended for most folks!

Budget, Warranties & Final Inspection for Mobile Home Installation

Nobody likes financial surprises, especially with something as significant as your new home. Let’s break down what you can expect to pay for your mobile home installation.

Basic setup costs typically start around $1,500 for single-wides and $3,000 for double-wides, but complex installations can climb to $20,000 or more depending on your site’s conditions. Foundation costs vary widely based on type (remember that foundation table from Step 1?), while utility connections generally run $1,000-$5,000 depending on distance and complexity.

Don’t forget to budget for permits ($0-$1,000) and possible impact fees, which can reach up to $20,000 in some areas. Here at Manufactured Housing Consultants, we offer a handy cost calculator to help estimate these expenses for your specific situation. Our lowest-price pledge means you’ll get the best possible value, and we’re always transparent about costs.

Worried about paying for everything at once? Many lenders offer financing options that roll both the home purchase and installation costs into a single loan. Our financing specialists can help explore these options, regardless of your credit situation.

When it comes to warranties, you’ll want to understand what’s covered and what’s not:

Your manufacturer’s warranty covers the home structure and factory-installed components, while a separate installation warranty from your installer covers the setup work. Optional extended warranties provide additional coverage if desired.

Here’s an important detail many people miss: manufacturer warranties typically don’t cover installation issues. That’s why having a separate installation warranty is so crucial.

Before you can move in, your home needs to pass a final inspection to receive a Certificate of Occupancy. This inspection verifies that all aspects of the installation comply with applicable codes.

We strongly recommend including a 10% retention clause in your installation contract. This means you hold back 10% of the payment until the final inspection passes, you receive your Certificate of Occupancy, all warranty documentation is in your hands, and any punch-list items are fixed.

For extra peace of mind, consider hiring an independent home inspector (typically $200-$400) to do a thorough review before making your final payment.

That new manufactured homes typically settle during the first 60-90 days after installation. Don’t panic if you notice minor wall cracks or doors that suddenly don’t close properly—this is normal. Good installers will return to make adjustments after this settlement period.

At Manufactured Housing Consultants, we stand behind every home we sell. Our team in Laredo, Texas is committed to ensuring your mobile home installation goes smoothly from the first permit application to the final walkthrough. We partner with experienced, certified installers who understand that proper setup is essential for you to enjoy your new home for years to come.

Conclusion

Finding your perfect manufactured home is just the first step of an exciting journey. The real magic happens during mobile home installation – that critical process that transforms your house into a home you’ll love for years to come.

Throughout this guide, we’ve walked through the seven essential steps that ensure your home stands strong, stays safe, and maintains its value. From preparing the perfect site to that final, satisfying walk-through inspection, each phase plays a vital role in your home’s future performance.

Here’s the truth that we’ve seen time and again at Manufactured Housing Consultants: cutting corners on installation is never worth it. In fact, more than half of all complaints from manufactured homeowners stem from improper installation issues. That’s why most states, including Washington, require certified professionals who understand the unique requirements of manufactured home setup.

We understand that buying a home is one of life’s biggest investments, both financially and emotionally. That’s why our team in Laredo, Texas is committed to making your experience as smooth and stress-free as possible. We specialize in helping folks from all walks of life find affordable manufactured, modular, and tiny homes that match their dreams and their budgets.

Our approach is simple: offer a wide selection from 11 top manufacturers, provide financing options for every credit situation (yes, even if your credit isn’t perfect!), and guarantee the lowest prices – period. We’ve built our reputation on being straightforward, honest, and truly caring about our customers’ long-term satisfaction.

Whether you’re just starting to explore the idea of manufactured housing or you’re ready to make your move, we’re here to guide you through every step – from selection to financing to that all-important mobile home installation. We believe everyone deserves a beautiful, affordable home to call their own, and we’d be honored to help make that happen for you.

Ready to take the next step? Contact us today to find how we can help you become a proud manufactured homeowner with a properly installed home that will stand the test of time.