Why Mobile Home Plumbing Systems Are Different From Traditional Homes

What type of plumbing is used in mobile homes differs significantly from site-built houses in materials, routing, and installation methods. Here’s what you need to know:

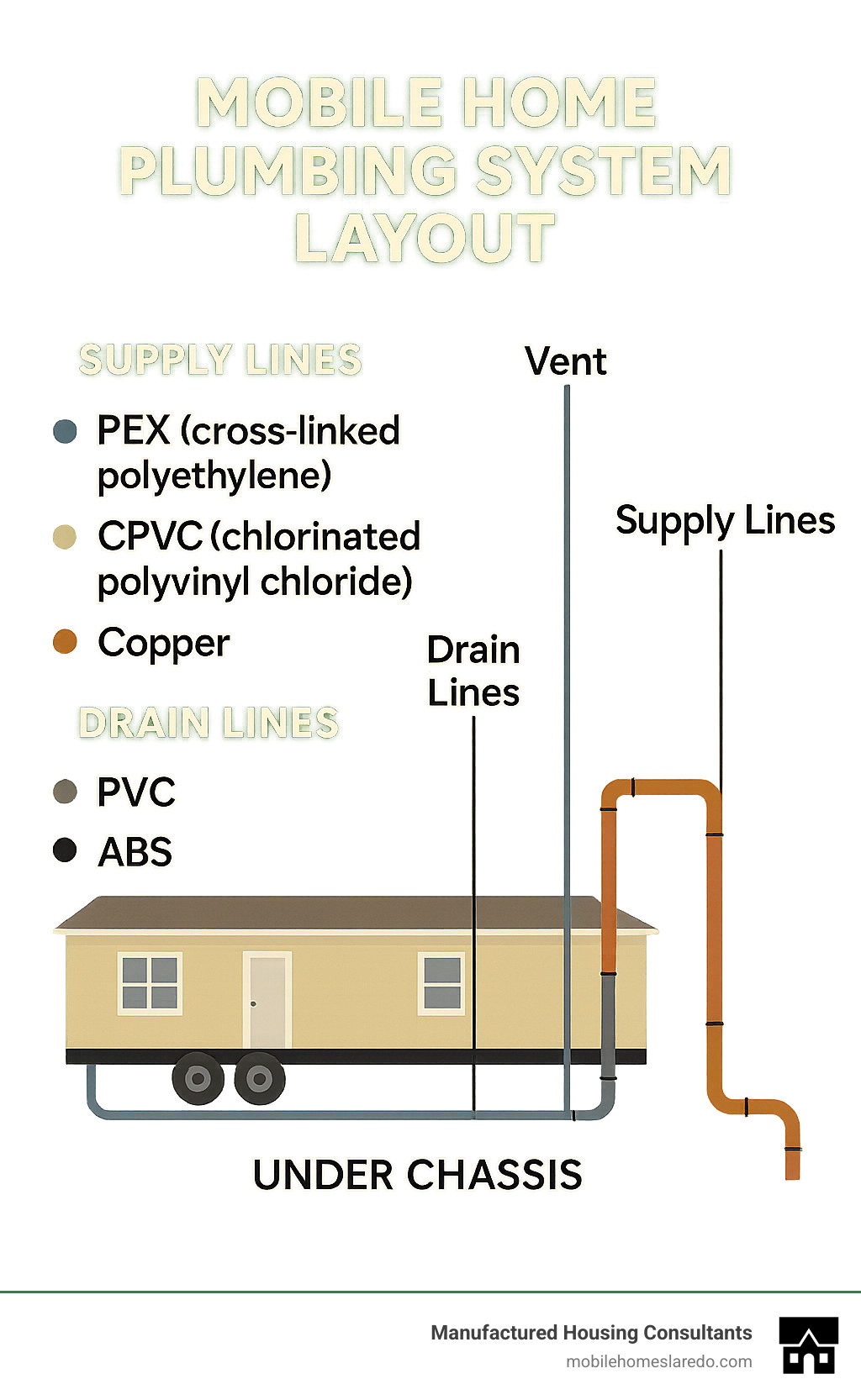

Supply Lines (Fresh Water):

- PEX (cross-linked polyethylene) – Most common in modern homes

- CPVC (chlorinated polyvinyl chloride) – Heat-resistant plastic

- Copper – Found in older units, being phased out

- Polybutylene – Banned material (1970s-1990s homes need replacement)

Drain & Waste Lines:

- PVC – Standard for drain pipes

- ABS – Alternative drain material

- Typically 3″ diameter vs 4″ in site-built homes

Key Differences:

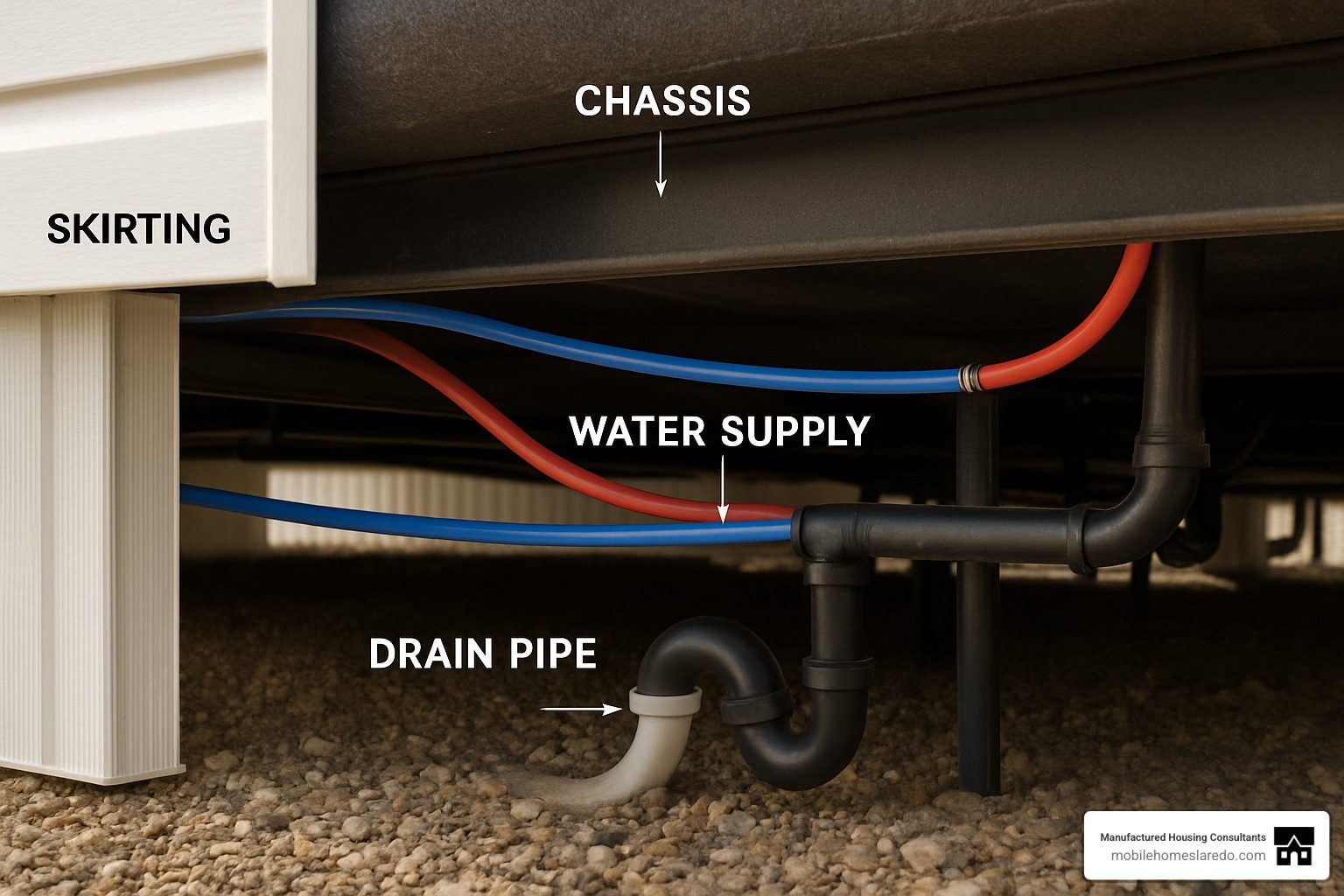

- Pipes run under the home, not inside walls

- Lines rise from floor instead of walls

- Smaller pipe diameters to save space and weight

- More freeze risk due to exposed under-floor location

The biggest surprise for new mobile home owners? Your water lines don’t come through walls like traditional houses. Instead, they snake through the “belly board” underneath your home and pop up through the floor near fixtures.

This unique setup affects everything from repairs to winterization. Understanding these differences helps you maintain your system properly and know when to call for help.

Basic what type of plumbing is used in mobile homes terms:

What Type of Plumbing is Used in Mobile Homes? Materials, Sizes & Routing

If you’ve ever wondered what type of plumbing is used in mobile homes, you’re looking at a fascinating evolution story. Before the mid-1980s, manufacturers used galvanized steel, copper, and cast iron. Then the plastic revolution hit, and everything changed.

Today’s manufactured homes primarily use PEX, CPVC, PVC, and ABS – and there’s smart thinking behind these choices. PEX costs about one-third less than copper and handles temperatures from 32°F to 200°F. Its superpower? It bends into 90-degree turns without breaking, meaning fewer joints and fewer leak points.

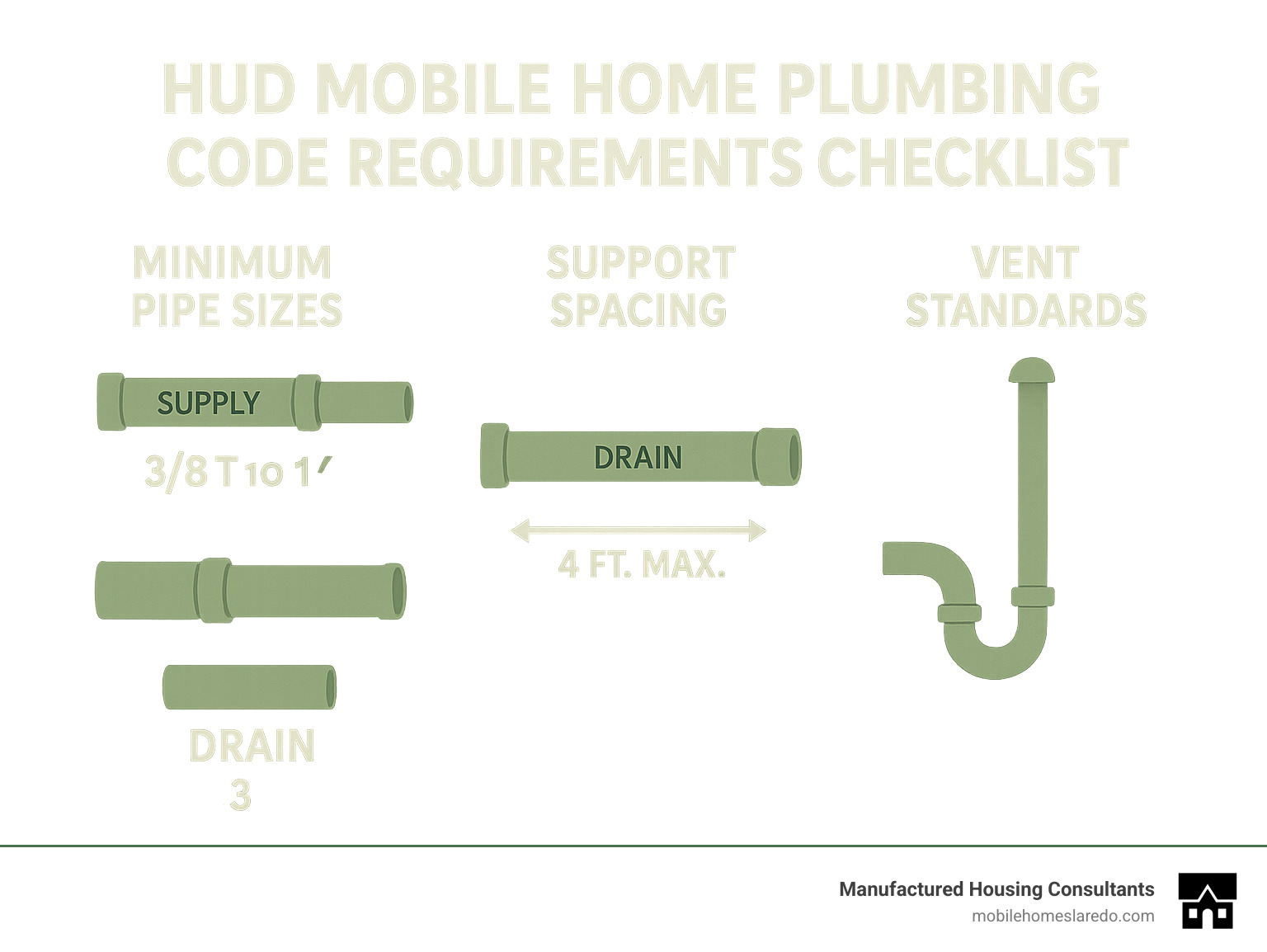

Mobile homes get clever with sizing. Supply line diameters typically run from 3/8″ to 1″, while drain lines are usually 3″ ABS instead of the 4″ you’d find in a site-built home. It’s all about working within space and weight limits.

The routing system is where things get interesting. Instead of snaking pipes through walls, mobile home supply lines run under the floor alongside HVAC ducts, then pop up through floor joists. This factory-built approach makes construction smoother but creates unique repair challenges.

| Material | Cost vs Copper | Temperature Range | Flexibility | Lifespan | Best Use |

|---|---|---|---|---|---|

| PEX | 33% less | 32°F-200°F | Excellent | 40-50 years | Supply lines |

| CPVC | 50% less | Up to 200°F | Good | 25-40 years | Hot water supply |

| Copper | Baseline | -40°F-400°F | Poor | 50-70 years | Legacy systems |

Scientific research on PEX advantages backs up what we see every day – PEX’s flexibility and freeze resistance make it perfect for mobile home living.

Understanding Supply Lines – What Type of Plumbing is Used in Mobile Homes for Fresh Water

For fresh water delivery, PEX tubing has become the star in modern mobile homes. Its color-coding system – blue for cold water, red for hot – makes life easier for homeowners and plumbers working in tight spaces.

CPVC remains popular for both hot and cold supply lines. It’s budget-friendly and uses glued joints for permanent connections. Since CPVC matches copper’s outer diameter, replacing old copper lines becomes much easier.

You might still find copper in older mobile homes. While copper offers excellent corrosion resistance and lasts decades, it’s being replaced by plastic alternatives due to cost and installation complexity.

If your mobile home was built between the late 1970s and mid-1990s, you could have polybutylene (PB) pipe. This material was banned due to widespread leakage problems. Many insurance companies won’t cover homes with PB piping still installed.

Pressure ratings matter more than you might think. Mobile home supply lines need to handle standard municipal water pressure (40-80 PSI) while dealing with natural movement and settling. This is where PEX really shines – its flexibility absorbs stress that would crack rigid pipes.

Drain & Vent Choices – What Type of Plumbing is Used in Mobile Homes for Waste Removal

For wastewater removal, what type of plumbing is used in mobile homes focuses on PVC and ABS materials. PVC largely replaced ABS after we found that ABS breaks down when exposed to sunlight.

The drainage system needs a slope of 1/4″ to 1/2″ per foot to keep things flowing with gravity’s help. Achieving consistent slope under a mobile home’s chassis takes planning during installation.

Clean-outs are required at every 360-degree turn before the main drain, though mobile homes typically have fewer clean-outs than site-built homes. This can make clearing main line clogs more challenging.

Venting in manufactured homes often uses air admittance valves (“dry vents”) under sinks instead of multiple roof stacks. These one-way valves let air into the drainage system while keeping sewer gases out of your living space.

Federal regulations require properly vented plumbing systems, typically through direct roof vents (VTR) that maintain proper air pressure for waste flow. The P-shaped trap in drain lines creates a water barrier to block sewer gases.

More info about mobile home installation covers how these systems connect during setup.

Routing & Access Points: Finding Pipes Under the Chassis

The belly board system makes manufactured housing unique. Your pipes run through this enclosed space beneath the flooring, wrapped in insulation to prevent freezing. This protects pipes from weather but makes access trickier than wall-mounted systems in traditional homes.

Heat tape zones become essential in colder climates. The tape must be rated for your specific pipe material and kept powered throughout cold snaps. Most heat tape lasts three to five years and should only connect to GFCI-protected outlets.

Access panels are placed strategically for maintenance, but they’re not as plentiful as clean-outs in basements. Knowing where these panels are located and how to remove them safely can save time and money.

The chassis construction means pipes experience more movement than in site-built homes. Pipes should be supported every 4 feet maximum to prevent sagging and joint failure.

With scarce cut-off valves inside the home, your main shutoff valve becomes critical. It’s typically located near the utility room or outside at the hose bib.

Maintenance, Codes & When to Call a Pro

Living in a manufactured home means understanding different rules. HUD Code §3280 governs manufactured home plumbing requirements as federal standards rather than local ones. While HUD sets building standards, local codes take over once your home is set up for connections to septic or municipal systems.

What type of plumbing is used in mobile homes creates unique maintenance challenges. Those under-floor supply lines need more attention than pipes hidden safely inside walls.

We recommend checking your plumbing twice yearly – spring and fall work well. Focus on accessible belly board areas, looking for moisture, rust, or rodents that might damage insulation or pipes.

Winterization becomes absolutely critical in mobile homes. Supply lines running under the floor are much more vulnerable to freezing than pipes inside heated walls. Insulate exposed pipes, seal air leaks around the belly board, and maintain heat tape in good working order.

Common problems include frozen pipes, joints that leak as homes settle, clogged drains, and low water pressure. That low pressure often comes from something simple like a clogged faucet aerator – an easy, inexpensive fix.

Foul odors usually point to venting problems. Manufactured homes have proper venting systems configured differently than traditional homes, often using air admittance valves under sinks instead of multiple roof stacks.

Modern mobile home plumbing isn’t “substandard.” Materials like PEX often outperform copper pipes in older site-built homes. The difference isn’t quality – it’s design approach.

If your home was built between the late 1970s and mid-1990s, check for polybutylene pipes. This banned material had widespread failure problems. Many insurance companies won’t cover homes with polybutylene still in place. Complete PEX replacement is the only real solution.

More info about Types of Mobile Homes explains how different home styles affect plumbing configurations.

Scientific research on pipe materials provides deeper technical details about performance characteristics.

HUD Requirements & Local Code Checklists

HUD standards specify what to expect from your plumbing system. Supply lines must be between 3/8″ and 1″ in diameter, while drain lines are typically 3″ ABS. These sizes are specifically chosen for manufactured housing needs.

Support spacing can’t exceed 4 feet for horizontal pipe runs, preventing sagging that could stress joints or create freeze-prone low spots. Hangers must be rated for both pipe material and expected load.

Clean-out access points are required wherever drain lines change direction by more than 360 degrees. This means you should have cleaning access at major turns in your drain system.

Every fixture needs a P-trap – that curved pipe section holding water to block sewer gases. These only work properly with adequate system venting.

Vent rules ensure proper air flow through your drainage system via traditional roof stacks or approved air admittance valves. The goal is preventing sewer gas intrusion while allowing proper drain flow.

Inspection points focus on basics: joint integrity, proper drain slope, adequate pipe support, and required clearances. Plastic supply pipes must stay 18 inches from water heaters, and all piping should be at least 6 inches off the ground.

DIY Maintenance vs Calling a Plumber: Decision Tree

Knowing when to DIY versus call for help saves money and headaches. The key is understanding your limits and potential consequences.

You can handle basics yourself. Learn to shut off your main water supply – find that larger valve next to your outside hose faucet and turn clockwise until it stops. Always test by running an indoor faucet.

Using a plunger correctly is essential. Flange-type plungers work for toilets, cup-type for sinks. Maintain a good seal and work for about 20 seconds before checking results.

Installing heat tape isn’t difficult, but follow manufacturer instructions exactly and always use GFCI-protected outlets. Replacing faucet aerators and basic fixture maintenance are also DIY-friendly.

Call professionals for serious issues. Major leaks, sewer line problems, persistent clogs, and polybutylene replacement need expert attention. Electrical issues with heat tape or pumps are also beyond most homeowners’ comfort zones.

Any work requiring permits or code compliance should go to licensed professionals. Doing it right the first time costs less than fixing DIY disasters.

Cost versus risk analysis matters. A $20 plunger solves 90% of toilet clogs, making it a no-brainer DIY fix. But attempting major leak repairs without proper knowledge can cause thousands in water damage.

Check warranty considerations. Many manufactured homes come with plumbing system warranties. Unauthorized repairs might void these protections.

At Manufactured Housing Consultants, we’ve seen every plumbing issue across our Texas locations. Working with 11 top manufacturers gives us insight into common problems and best solutions for different home models.

Emergency situations require immediate professional help: water spraying from pipes, sewage backing up, gas odors near plumbing, electrical sparks around water equipment, or structural damage from leaks.

If you can’t find your main shutoff valve, look for your water meter and use a meter key. In a pinch, tape a screwdriver to a wrench handle to form a T-shape.

More info about mobile home relocation services covers how plumbing systems are protected during moves.

Understanding what type of plumbing is used in mobile homes puts you in control of your home’s most important systems. Whether shopping for a new manufactured home or maintaining your current one, this knowledge ensures reliable service for years to come.

The bottom line? Mobile home plumbing isn’t inferior – it’s engineered for a different application. Modern materials often outperform traditional options, and proper maintenance keeps everything flowing smoothly. When unsure about something, consult professionals who understand manufactured housing requirements.